Bringing 3-D Power to the People

Bringing 3-D Power to the People? The New York Times, March 27, 2014 I’m one of those people …as a designer I knew I had to learn about 3-D printing but what I didn’t know is that I’d fall in love with it.

I’ve had my own interior-design business for 25 years and, yes, things have changed since my first hand-drawn working drawings for my first client. I just finished writing an article for the online magazine Better After 50 talking about my discovery of 3-D printing.

I decided to use this technology to help produce a sofa commission. As I create more and more furniture, 3-D printing will definitely be a tool that I will use. For those of you who have wondered how these things get created, here’s the steps that I went through to produce the final product:

I start by drawing a rough sketch with dimensions. The arm slopes downward which was difficult to convey in my rough sketch.

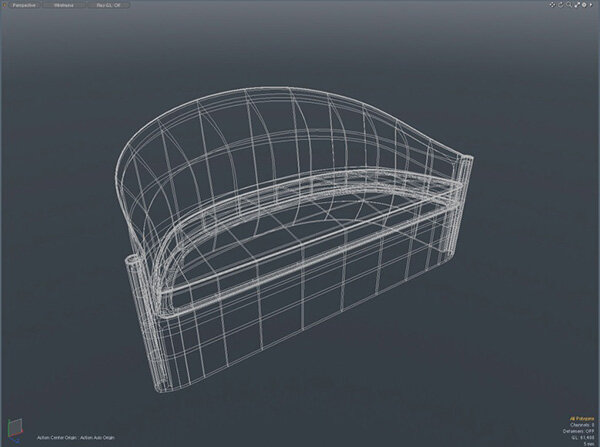

My fab draftsperson interprets my rough drawing. In this stage I can maneuver the drawing in a program called MeshLab so I can see the sofa at all angles.

Once I finalize all aspects of the sofa, it is then put into the 3-D printing program. This step is complicated by the fact that the drawing is created from the inside out, using a completely different methodology.

And voila! My first 3-D printed object in plastic so well done by the company Shapeways. This is about 8 inches long. I took this to my upholsterer’s framer and said: build this! The arms were complicated to explain and this model did that perfectly.

Here’s the frame raw. I was able to further draw – right onto the frame – a tweak to the arm curve. There’s still nothing like seeing the real thing.

The next step is to cover the frame in foam with hand-tied springs and webbing. At this stage I brought in the client for a sit test; if we want to make the seat softer or firmer, or the back slightly different in pitch, this is the time to do that.

The Finished Sofa!